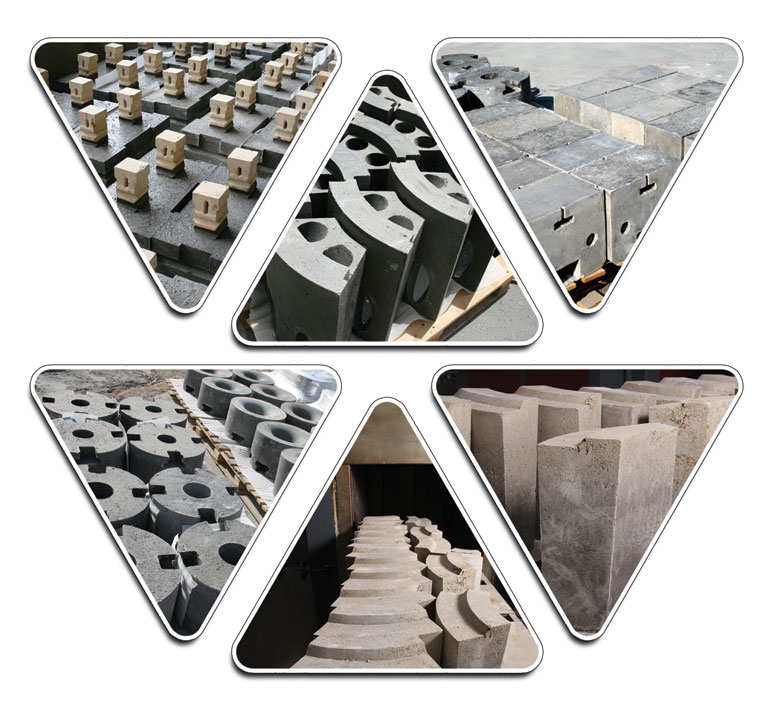

Advanced refractory piece

Refractory parts are made in French Yazd from half a kilogram to ten tons.

These parts are produced with high quality raw materials and the production process is designed for them to be sensitive. Refractory parts are manufactured with European machinery and Curing is performed in a very professional and precise manner. Double-walled dryers and electric furnaces are circulated by hot air and their thermal graphs are carefully monitored by Japanese programmers. After-sales service leads to the correct use and increase of product efficiency for customers.

Refractory parts, like refractory masses, require high sensitivity and accuracy to be able to perform their use in the best possible way.

Due to the use of high-quality mass and sensitive and accurate production methods, refractory parts in Yazd French also have a very high quality. High percentage of water control and Curing (initial preheating) with high sensitivity, has made Yazd’s French capable of producing high-strength refractory parts with excellent shapes.

Due to the possibility of making high-precision molds, vibrating and adjustable tables, dryers and programmable electric ovens that have the ability to run different thermal graphs, and due to the fact that they circulate heat, very clean and high quality parts are made.